Waterjet Cutting Arkansas

CUT ANYTHING…WITH PRECISION

Waterjet Cutting Arkansas

The fastest growing manufacturing technology in the world.

Need complex cuts?

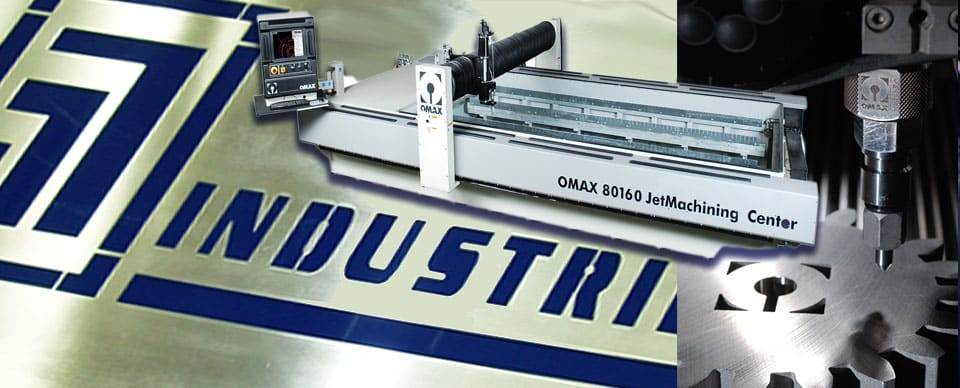

We can provide them with our new OMAX 80160 JetMachining® Center. Tolerance and accuracy is within +/-.003″ and waterjet cutting leaves no burrs or thermal distortion.

AZ Industries offers industry leading, top quality and fast turnaround Water Jet Machining and Waterjet cutting services. We serve numerous industries, and can work rapidly on any project your firm or organization may require. AZ Industries is a top company for Waterjet Cutting In Arkansas.

With no material hardening or stress, we offer the best nesting ability possible. AZ Industries Waterjet Cutting Arkansas. We offer full service professional precision laser and waterjet services.

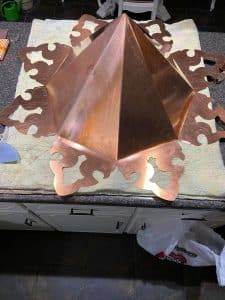

Exotics

Architectural materials

Waterjet Cutting in Arkansas for a wide range of materials

Our services are ideal for fast-paced demands such as aftermarket automotive, motorcycle and aerospace parts.

Quick turnaround with almost no set-up time offers the flexibility you require.

Virtually any job requiring maximum material yield

AZ Industries is dedicated to providing high quality, cost effective solutions for your machining needs. With our OMAX® 80160 bridge-style abrasive waterjet we can provide complex cutting of virtually any material. This state of the art technology offers flexibility and fast-turnaround from prototype to production.

Large scale precision machining: For larger parts or multiple parts from large stock up to 6′ x 12′.

COMPETITIVE COST

FLEXIBILITY & SPEED

ACCURACY & REPEATABILITY

We are always happy to quote your projects large or small!

Call us today to discuss your specifications or email your part files to [email protected]